Loading...

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Magna fringilla urna porttitor

Mi bibendum neque egestas congue quisque egestas. Id diam maecenas ultricies mi eget mauris pharetra et ultrices. Imperdiet massa tincidunt nunc pulvinar sapien.

Rhoncus dolor purus non enim praesent elementum facilisis leo. Ultricies leo integer malesuada nunc vel risus commodo. Diam sollicitudin tempor id eu nisl nunc.

Your organization has performed professionally. Your commitment to quality and the efforts in ensuring the ultimate success of this project were wonderful.

It is very enjoyable to work with Top Project. They are consistently courteous and friendly, respond and solve problems quickly, and are very knowledgeable.

Throughout the post-construction phase of our new office, Top Project has been a visible force in getting “punch list” items completed and done right the first time.

Our store is truly a compliment to your organization. We have been tremendously impressed with your professionalism, workmanship and timeliness.

When it comes to the quality factor, Akbar Brothers is renowned for focusing on continuous innovations of product lines, packaging and processing.

Stringent quality control at Akbar Brothers’ premises has been primarily entrusted to a workforce of over thousand dedicated, experienced and qualified personnel. Each consignment undergoes rigorous quality checks and tests by experienced tea tasters and quality supervisors during every stage of production up to the time of shipment. Nevertheless, since quality of Ceylon tea is a time-honoured tradition in the Akbar brothers’ family, a family member is always at hand to personally check into the quality of tea.

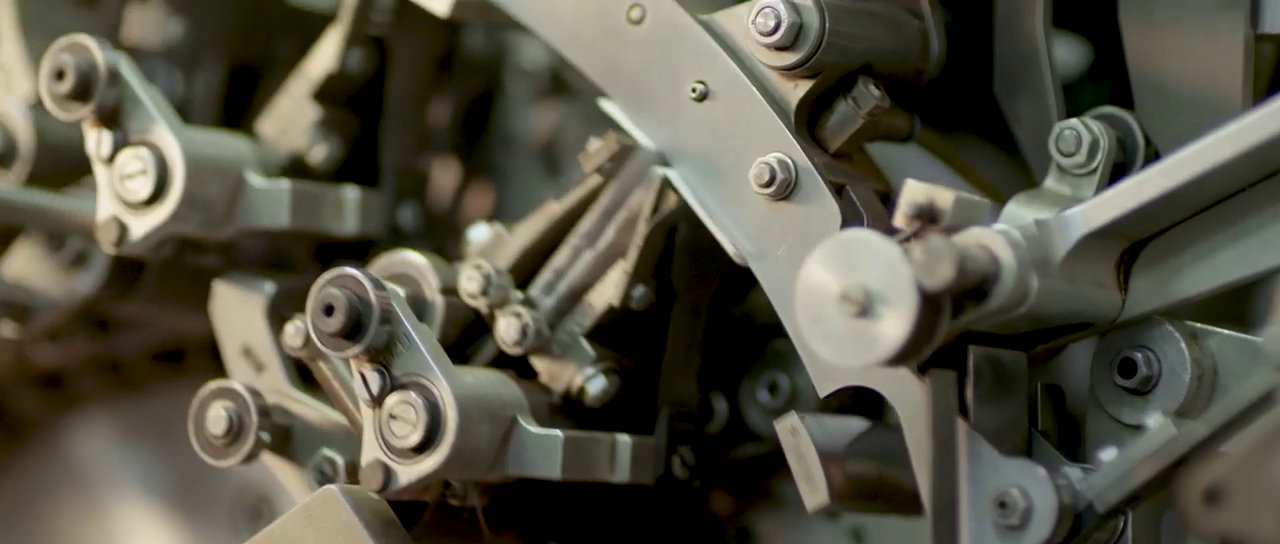

Akbar Brothers utilizes state-of-the-art machinery from Germany, Italy and Japan for its automated tea cleaning, tea blending, tea flavouring and tea packing facilities.

Further, an ultra-modern packing Complex over 300,000 square feet has been built in Kelaniya to service Do Ghazal Ceylon tea’s packing operations. The packing complex is equipped with modern automated technology to ensure minimum handling and maximum hygienic standards.

Do Ghazal Ceylon tea ensures uncompromised quality, especially the purity and wholesome freshness which is a vital feature that promotes the authentic Ceylon tea taste. The tea’s brand strategy is to maintain and expand the focus of being a premium blend of Ceylon Tea, sought after by customers worldwide for its flavor and aroma.

The Covid19 pandemic in 2020 changed the way businesses operate across the world. We resumed operations by administering new hygiene and safety measures from our factory to offices, giving priority to well-being of all our stakeholders.

Hygiene and Safety Measures

Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP) were implemented across the factory and offices. The premises were installed with foot-operated pedals, automated washing facilities, sanitizers at every entrance, thermometers and other equipment that would help minimise physical contact and allow detection. The staff received training of all preventive and emergency measures and all government-imposed regulations are being followed.